Laminations

Sondor Industries has extensive experience in manufacturing custom solutions via lamination. Foam Lamination is an essential process for making foam composites, which combines two kinds of materials to work as one part. Our lamination capabilities coupled with our access to a wide variety of foams, plastics and other speciality materials provide our customers with a turnkey solution that can solve their unique component and packaging challenges.

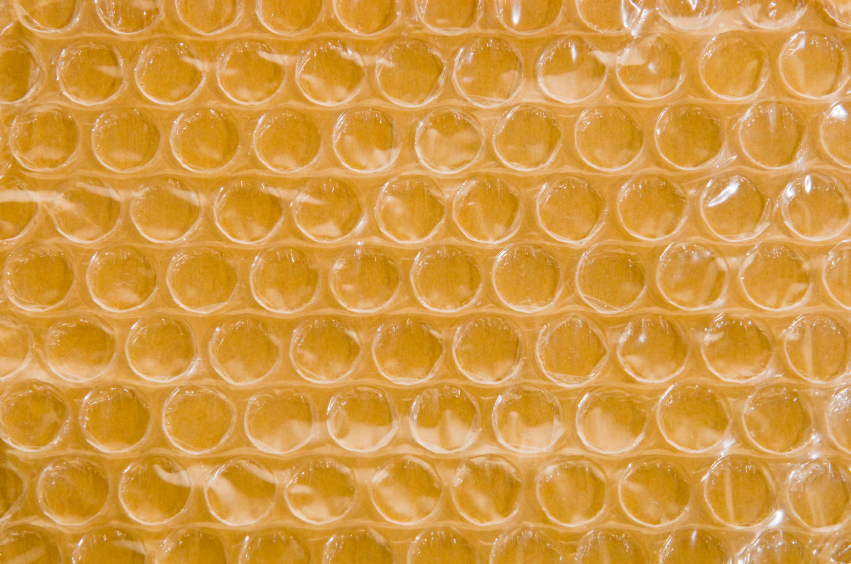

Sondor can laminate a variety of materials to various rubber, plastic foam substrates, Aerothene, and Performance Bubble wrap according to customer specifications. Laminations are available for almost any application. The typical methods are PSA and Flame lamination (heat lamination).

PSA lamination

PSA (Pressure Sensitive Adhesive) lamination is a process that creates foam sheets or rolls with adhesive backing. Sondor's adhesive laminator performs PSA lamination. After one roll of foam goes through the adhesive laminator, it is applied with a layer of adhesive back on one side together with the release liner.

This application is typically used for foam rolls. PSA lamination is essential in making adhesive foam tapes such as our Strip & Tape.

Flame / Heat / Thermal Lamination

Flame Lamination is also called heat or thermal lamination. Sondor's Flame laminator can create high temperatures, which melts foam on its surface. When two pieces of foam sheets go through the heat lamination machine simultaneously, they can bond together firmly with a hot melted surface.

Flame lamination can be used for both foam sheets and foam rolls, and is compatible with multiple materials.

Applications

- Furniture

- Agriculture

- Automotive

- Construction and roofing

- Pharmaceutical

- Glassware, electronics etc.

Advantages

- A sophisticated way to bond foam with foam or other materials together.

- LDPE (low density polyethylene) raw material used in manufacture is chemically unreactive and non-irritant, regarded as biologically inert and fully recyclable

- Excellent shock absorption characteristics for fragile goods

- Good insulating properties

- Closed-cell structure ensures dust, water, and wind resistance

- Non-toxic

- Chemical and UV resistant

Custom Applications

- Can be manufactured in various weight/ strength categories

- Can be laminated to a number of materials - paper, foil, plastic, and Performance Bubble wrap

- Aerothene and Performance Bubble wrap rolls can be split into quarters, thirds, halves, or any width required

- Both Aerothene and Performance Bubble wrap can be converted into sheets, bags, or pouches to customer specification

With branches across South Africa in Cape Town, Durban, Gauteng, Pretoria and Gqeberha, our knowledgeable representatives can advise the right solution for you. Find a branch near you for expert assistance.