Foam Sheeting

Sondor can supply Polyethylene and EVA foam sheeting to any thickness and density required. Sondor also provides cross-linked and non-cross-linked polyethylene sheeting, such as SPX and Aerothene (LDPE).

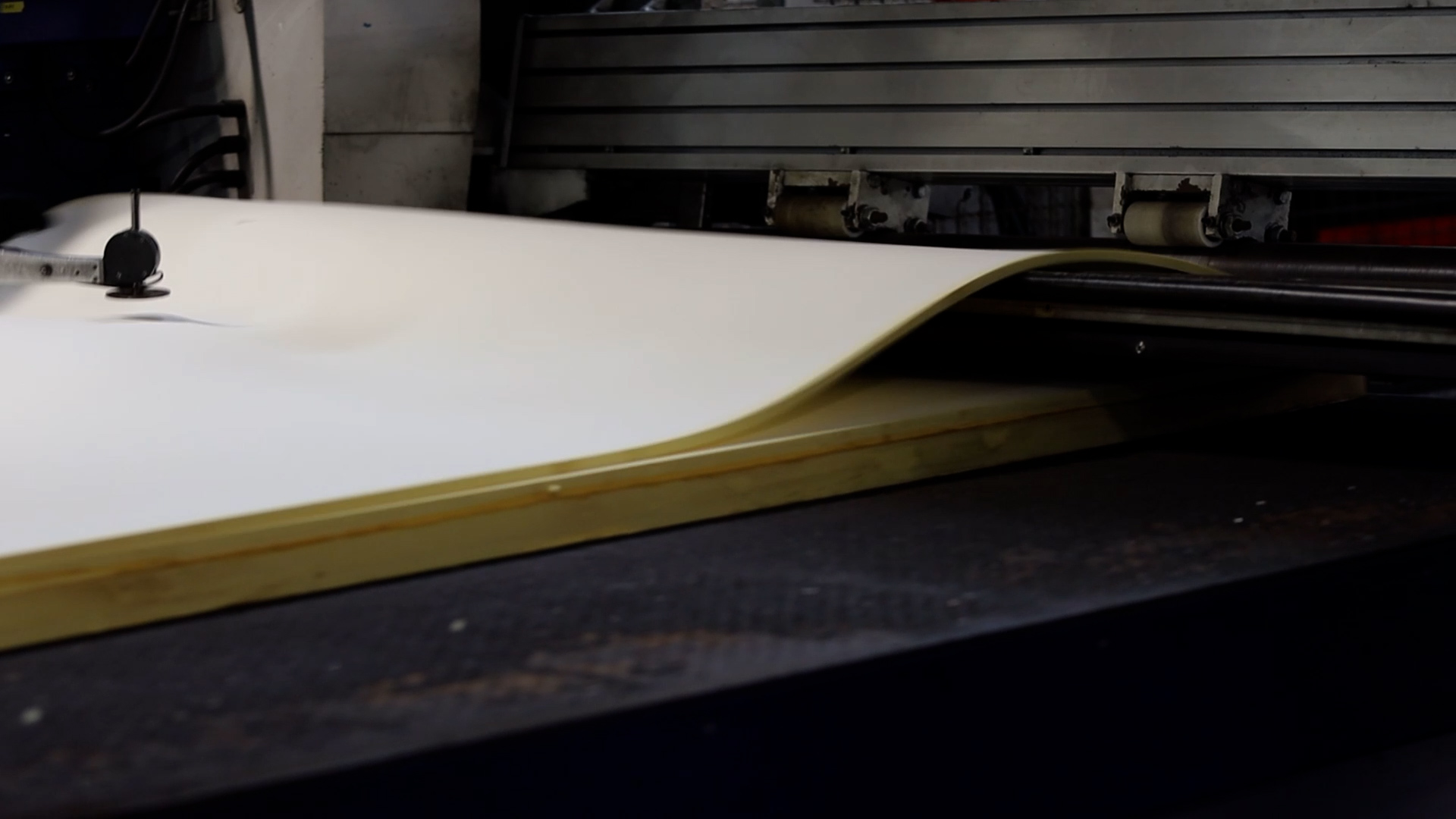

How is foam cut into sheets?

To cut foam into sheets, a special type of cutting machine is typically used. This machine works by moving a grinding head across the foam surface at high speeds. As the foam passes under the grinding head, tiny particles are shaved off and are scraped up in a sheet by special foam cutting blades. Once the foam sheet has been fully cut, it can then be rolled or folded for easy storage and transport. While cutting foam to sheets may seem like a simple process, it requires careful attention to detail in order to achieve clean, even cuts every time. Fortunately, with the right machinery and expertise, foam can be easily and efficiently converted into a wide variety of useful foam products.

Applications

- Automotive ceilings

- Floor underlaying

- Noise insulation

- Movement insulation

- Anti-vibration solution

- Marine

- Defence

- Medical

- Used for all-purpose mats in Sports, Leisure and Medical uses as with Sondor's Trailmat

- Used in the fabrication of carnival floats, models and pontoons

Advantages

- Sondor can provide sheeting with or without adhesive backing

- We can supply custom sizes and cut-to-spec sheeting

- Sondor foam is water-resistant

- Sondor foams are weather and UV stable

- Wide range of colours available

- Wide range of densities available

- High strength and durability

- Fire resistant

- Cost-effective

With branches across South Africa in Cape Town, Durban, Gauteng, Pretoria and Gqeberha, our knowledgeable representatives can advise the right solution for you. Find a branch near you for expert assistance.